Introduce

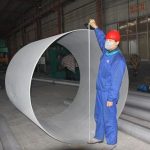

High-efficiency stainless steel welded pipe is a pipe made by welding stainless steel sheets or plates together. The welding process involves heating the steel to high temperatures, melting the edges of the sheets, and then cooling the weld to form a strong bond. Stainless steel welded pipe is commonly used in the construction, automotive, and oil and gas industries due to its high corrosion resistance and strength.

There are several types of stainless steel welded pipe including durable sch 10 stainless steel pipe, ferritic and duplex stainless steel. Austenitic stainless steel is the most common type because it has excellent corrosion resistance and is easy to weld. Ferritic stainless steels have lower corrosion resistance than austenitic steels but are stronger and more heat resistant. Duplex stainless steels are a combination of austenitic and ferritic steels that offer greater corrosion resistance than either alone.

The process of manufacturing stainless steel welded pipe starts with a flat or stainless steel sheet. These sheets are cut to the desired length and width, and a series of rollers are used to shape them into a cylindrical shape. The edges of the sheet are then ground down to a smooth surface in preparation for welding.

There are several methods that can be used to weld stainless steel pipe, including TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and stick welding. TIG welding is a popular method of welding stainless steel pipe because it produces high-quality, clean welds with minimal distortion. In TIG welding, an arc is formed between a tungsten electrode and the workpiece, melting the edges of the steel plate and forming a strong bond. MIG welding is similar to TIG welding, but it uses a continuous wire-fed electrode instead of a tungsten electrode. Stick welding, also known as shielded metal arc welding (SMAW), is another method that can be used to weld stainless steel pipe, but is less commonly used due to the lower quality welds it produces.

After the weld has cooled and hardened, inspect the welded pipe for defects. Any defects found are repaired using a process known as rework, which involves grinding down defective welds and then rewelding them. The pipe is then tested to ensure it meets the required strength and corrosion resistance standards.

Advantages of efficient stainless steel welded pipe

- Its high corrosion resistance, which makes it suitable for a wide range of environments.

- The stainless steel welded pipe is also durable and has a long service life.

- In addition, it is easy to clean and maintain, and has an attractive appearance.

In summary, stainless steel welded pipe is a strong and durable pipe material that is widely used in various industries due to its high corrosion resistance and strength. It is made by welding together stainless steel sheets or plates, which can be welded using a variety of methods including TIG, MIG, and stick welding. While it has several advantages, including longevity and aesthetics, it is also more expensive and more difficult to cut and join than other types of pipe.

Performance of high-efficiency stainless steel welded pipe

Efficient stainless steel welded pipe is made from a combination of different alloys, the most common of which is chrome. Chromium is added to steel to form an alloy that is highly resistant to rust and corrosion. Other alloying elements, such as nickel and molybdenum, can also be added to stainless steel to enhance its properties.

One of the key properties of stainless steel welded pipe is its corrosion resistance. The chromium in the alloy forms a passivating layer on the pipe surface that prevents rust and corrosion. This makes welded stainless steel pipe ideal for use in environments where piping is exposed to moisture or chemicals, such as chemical processing plants, food processing facilities, and marine environments.

Another important property of stainless steel welded pipe is durability. Stainless steel is a strong and durable material that can withstand high pressure and high temperature. This makes it ideal for use in applications where the piping will be subjected to high stress, such as piping and structural applications.

In addition to corrosion resistance and durability, stainless steel welded pipe is also known for its ease of fabrication. Stainless steel is easy to cut, weld and form, making it a versatile material for a wide range of applications.

The use of high-efficiency stainless steel welded pipe

- Oil and Gas Production: Commonly used in the oil and gas industry for its corrosion resistance and durability. It is used to move crude oil and natural gas from wells to refineries and processing plants.

- Chemical Processing: It is also commonly used in chemical processing plants due to its corrosion resistance and ease of fabrication. It is used to transport chemicals such as acids and bases throughout the plant.

- Food processing: Because of its corrosion resistance and easy cleaning, it is widely used in the food processing industry. It is used to transport food and make conveyor belts, storage tanks, and other food processing equipment.

- Pharmaceutical: Also used in the pharmaceutical industry. Corrosion-resistant, non-toxic, easy-to-clean material, suitable for transportation and storage of various pharmaceutical products and chemicals.

- Marine environment: It is used in marine environment because of its corrosion resistance. It is used in the construction of ships, offshore platforms, and other marine structures, as well as in desalination plants and coastal power plants.

- Construction: Stainless steel welded pipes are often used in the construction of buildings, bridges, and other structures. They are strong, durable, and corrosion resistant, making them ideal for use in exposed or harsh environments.

Related Products