Stainless steel pipes are essential components in various industries due to their corrosion resistance, strength, and durability. When it comes to choosing the right stainless steel pipe for your project, two primary options are available: seamless and welded. Each type has its advantages and considerations, making it crucial to understand the main differences between them. This article explores the manufacturing processes, cost implications, applications, and performance characteristics of seamless and stainless steel welded pipes, providing valuable insights to help you make informed decisions.

Understanding the Manufacturing Processes

Seamless Stainless Steel Pipes: A Peek into Precision

The production of seamless stainless steel pipes begins with a solid cylindrical steel billet. This billet is heated and then stretched or pulled over a form until it forms a hollow tube. This method, known for producing pipes without any welds, ensures a high degree of uniformity and integrity across the entire circumference of the pipe. The seamless process is inherently more labor-intensive and requires more sophisticated equipment, which contributes to the higher cost of these pipes.

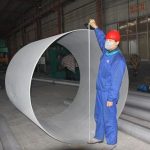

Stainless Steel Welded Pipes: The Art of Joining

Contrastingly, stainless steel welded pipes are fabricated by bending steel into a tube shape and welding along the seam to secure it. Advances in welding technology, including Electric Resistance Welding (ERW) and Laser Welding, have significantly enhanced the quality and durability of the weld seam. This method is notably versatile, allowing for a broader range of sizes, lengths, and diameters, and is more economical, particularly for large-scale productions.

Deciphering Cost Implications

The distinct manufacturing techniques of seamless and stainless steel welded pipes directly influence their market prices. Seamless pipes command a premium due to their intricate production process and the high level of uniformity and pressure resistance they offer. Conversely, welded pipes present a more cost-efficient option, making them an attractive choice for projects where budget constraints are a primary consideration.

Diverse Applications: Matching Pipe to Purpose

High Demand Scenarios: The Domain of Seamless Pipes

Seamless stainless steel pipes are the go-to choice in environments that demand high pressure, high temperature, and a seamless flow, such as in the power generation, chemical, and petrochemical industries. Their uniform structure without any welds translates into superior strength and reliability, making them ideal for critical applications where failure is not an option.

Versatile and Practical: The Role of Welded Pipes

Stainless steel welded pipes have a broad spectrum of applications, thanks to their adaptability in size and cost-effectiveness. They are extensively used in lower-pressure and temperature settings, including construction, architecture, water and sewage systems, and certain automotive and aerospace applications. Their flexibility and affordability make welded pipes a practical choice for a wide array of projects.

Performance Characteristics: A Detailed Examination

Strength, Reliability, and Corrosion Resistance

While seamless pipes offer unparalleled strength and reliability in challenging conditions, advancements in welding technologies have significantly narrowed the performance gap between the two types. Both seamless and welded pipes provide excellent corrosion resistance, a characteristic intrinsic to stainless steel. However, the weld area in welded pipes may require additional treatments to match the corrosion resistance of the rest of the pipe.

Durability and Maintenance Considerations

Seamless pipes typically exhibit superior durability due to their consistent material composition throughout. Nevertheless, with appropriate maintenance and quality welding practices, welded pipes can also achieve commendable longevity, especially in environments where corrosion is less of a concern.

Advanced Considerations in Pipe Selection

Seamless Pipes: Analyzing the Premium Choice

While seamless stainless steel pipes are often viewed as the premium option due to their uniformity and high integrity, it’s essential to delve deeper into when and why this premium is justified. In applications where the integrity of the fluid flow is critical, such as in high-purity applications for the semiconductor or pharmaceutical industries, the absence of any internal weld seam means there is less risk of contamination. Furthermore, the high-pressure endurance of seamless pipes makes them indispensable in the oil and gas industry, where pipe failure could have catastrophic consequences.

Welded Pipes: Emphasizing Versatility and Innovation

Welded pipes, on the other hand, have seen significant technological advancements that enhance their reliability and expand their applicability. Innovations in welding techniques, such as orbital welding, have improved the strength and consistency of the weld seams, reducing the susceptibility to corrosion and failure. Additionally, the ability to produce welded pipes in long, continuous lengths makes them ideal for modern infrastructure projects, such as water and gas distribution networks, where joints and fittings represent potential points of failure.

The Impact of Material Grades on Pipe Performance

When selecting stainless steel pipes, whether seamless or welded, the choice of material grade plays a pivotal role in determining the pipe’s corrosion resistance, strength, and suitability for specific environments. Grades like 304 and 316 stainless steel are common due to their excellent corrosion resistance and versatility. However, for more aggressive environments or specialized applications, higher-alloyed stainless steels such as super duplex or alloy 20 may be required to ensure longevity and performance.

Environmental and Economic Sustainability

In today’s world, environmental considerations and economic sustainability also play crucial roles in the decision-making process. Stainless steel welded pipes, with their lower carbon footprint and reduced material wastage, often emerge as the more environmentally friendly option. The efficiency of material use in welded pipe production, combined with the ability to use recycled steel, aligns well with global sustainability goals. On the economic front, the lower cost of welded pipes allows for budget allocations to be optimized or redirected towards other critical aspects of projects, enhancing overall project sustainability.

Future Trends and Innovations

The future of stainless steel pipes is closely linked to ongoing innovations in manufacturing technologies and materials science. Developments in additive manufacturing (3D printing) are beginning to impact the production of seamless pipes, potentially lowering costs and enabling more complex geometries. For welded pipes, advancements in automated and robotic welding are expected to further improve weld quality and efficiency, making welded pipes even more competitive.

Conclusion: Navigating the Choice

The decision between seamless and stainless steel welded pipes hinges on a delicate balance of factors, including cost, specific application requirements, and desired performance outcomes. Seamless pipes excel in high-stress, high-temperature situations where material integrity is critical. Welded pipes, conversely, offer a pragmatic and cost-effective solution for a vast range of applications, with their quality and reliability continually improving through technological advancements in welding. By comprehensively understanding these differences, stakeholders can ensure the selection of the most suitable type of stainless steel pipe for their project, optimizing both performance and cost-effectiveness.

Related Products