When looking for a durable and cost-effective material option for your next project, stainless steel welded pipe should be your first choice. This material is corrosion resistant and can be used in a variety of applications, making it a versatile choice for any project.

Introduce

1.1 What is Inconel Pipe

Corrosion-resistant welded pipe is welded by two stainless steel plates. The welds are then sanded smooth so they are not visible. Corrosion resistant welded pipe is a popular choice for many applications because it is strong and resistant to corrosion.

1.2 How it is manufactured

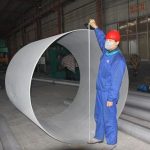

High quality stainless steel welded pipe is a steel pipe made by welding two steel pipes together. Welded pipes are made by welding two pipes together with a welder. Welded pipe is produced in a factory, and it is made by welding two pipes together with a welding machine.

1.3 Why use welded pipe

Welded pipe is made from a sheet of metal that is rolled into a tube and then welded shut. This type of pipe is durable and resistant to corrosion. For applications requiring high strength, welded pipe is a good choice.

1.4 Features

Welded pipe is made by welding two metal pipes together. This process creates a strong, leak-proof joint. It has many advantages over other types of pipes. First, it is corrosion resistant. This makes it ideal for applications where there may be exposure to chemicals or other harsh environments. Second, it is durable. Welded pipe can withstand high pressure and high temperature loads without failure. Third, it is easy to install. Welded piping can be installed using standard plumbing techniques. Finally, it’s cost-effective. Welded pipe is less expensive than other types of pipe.

Stainless Steel Welded Pipe Durable Material Selection

2.1 Multiple uses

High quality stainless steel welded pipe is a cost-effective and durable material choice for a variety of applications. Some of the most common applications for corrosion resistant welded pipe include:

- Process piping

- Steam and condensate lines

- Waterline

- Chilled water pipeline

- Air handling system

- Refrigeration system

- Durability

- Cost-effective

- Versatility

- Strength

- Corrosion resistance

2.2 Economical and durable material selection

Welded pipe is a cost-effective and durable material choice for a variety of applications. This material is ideal for construction and manufacturing applications where strength and reliability are critical. Stainless steel welded pipe is also resistant to corrosion, making it a good choice for use in harsh environments.

2.3 Diversity of applications

Welded pipe is a cost-effective and durable material choice for a variety of applications. Frequently used industries include the food and beverage, automotive, and pharmaceutical industries. The pipe is also popular in the construction industry for transporting water and other liquid resources.

How it was made

3.1 Manufacturing process

Stainless steel welded pipe is made by first welding two pieces of steel together. The welds are then ground and polished until smooth. The welded pipe is then cut to size and polished again. This process ensures that the welds are as smooth as possible and free from corrosion.

3.2 Annealing and finishing

Stainless steel welded pipe is made by first annealing the steel in a furnace. This softens the steel and makes it easier to weld. The pipes are then welded and sanded smooth. Finally, it is polished to a high gloss.

3.3 Testing and inspection

In order to ensure the welding quality, several tests and inspections are carried out. First, the weld is visually inspected to ensure it meets the required standard. Next, a radiographic inspection is performed to check the welds for any defects. Finally, a hydrostatic test is performed to ensure that the welds are strong and will not leak water.

3.4 Packaging and delivery

Packaging and shipping are very important to guarantee product quality. Pipes are usually packed in wooden crates and loaded onto trucks for transport.

craft

4.1 Welding process

High quality stainless steel welded pipe is the process of joining two or more pipes together by welding. This is done by heating the pipe to welding temperature and then applying a welding rod to the joint. The welding rod melts and joins the two pipes together.

4.2 Types

Stainless steel pipes are divided into three types: welded type, seamless type and drawn type. Welded pipe is made by welding a series of stainless steel pipes together. Seamless pipe is made by drawing a solid piece of stainless steel through a die to form a pipe. Drawn tube is made by drawing a solid piece of stainless steel through a die, then pulling the tube through a mandrel to form the desired shape.

4.3 Welding together

Welding stainless steel pipes together is the process of joining two or more pipes by heating them to welding temperature and then pressing them together. This process is commonly used to manufacture corrosion-resistant steel pipes, tubes made by welding a series of tubes together.

Advantages

5.1 Strength and durability

Corrosion resistant welded pipe is a popular choice for a number of reasons. It’s tough and durable, making it an excellent choice for applications that require a lot of wear and tear. Plus, it’s easy to maintain and doesn’t require much maintenance. If you are looking for reliable pipe that will last for many years, stainless steel welded pipe is a great choice.

5.2 Corrosion resistance

One of the advantages of high quality stainless steel welded pipe is corrosion resistance. Stainless steel is made from a mix of metals, including chromium and nickel, which help prevent rust and corrosion. This makes it an excellent choice for applications where exposure to harsh chemicals or moisture is possible.

5.3 Versatility

Stainless steel welded pipe is highly versatile, making it a popular choice for a variety of applications. It can be used in hot and cold environments and is resistant to a wide range of chemicals. Plus, it’s easy to clean and maintain, making it a popular choice for food and beverage applications.

Application

Stainless Steel Welded Pipe is a versatile product that is used in a variety of industries including the food industry. Some applications of stainless steel welded pipe in the food industry include:

- Food processing

- Food transportation

- Food storage

Stainless steel welded pipe is commonly used in the chemical industry for its corrosion resistance and strength. It can be used in a variety of applications, including conveying corrosive fluids and gases, and process piping. Stainless steel welded pipe is also a popular choice for food and beverage processing plants.

The oil and gas industry is one of many industries that use stainless steel welded pipe. high quality stainless steel welded pipe is used in the oil and gas industry in a variety of ways, from the transportation of oil and gas to the processing of these products, for the construction of pipelines and other oil and gas infrastructure.

Hunan Yasco as a stainless steel pipe supplier, we can provide polishing, welding, crimping, bending, drilling, cutting, rolling and some finished product processing, such as tank body, etc. We can also process according to customer’s drawings. For more information about ss pipe price, welcome to inquire!

Related Products

Stainless Steel Welded Pipe