Introduction:

Thin wall stainless steel tubes, commonly known as duplex pipes, have revolutionized the landscape of industrial tubing, offering a multitude of advantages over traditional materials. This article explores the intricate details of these tubes, focusing on their metallurgical excellence, corrosion resistance, mechanical strength, versatility, and economic viability. Understanding these key attributes is crucial for professionals across industries, guiding them towards a more efficient and reliable choice in tubing materials.

I. Metallurgical Excellence:

The distinctive metallurgical composition of thin wall stainless steel tubes forms the foundation of their exceptional performance. Featuring a duplex structure with both austenitic and ferritic stainless steel phases, these tubes amalgamate the corrosion resistance of austenitic steel with the high mechanical strength of ferritic steel. This dual-phase microstructure contributes to a material that surpasses traditional options, providing a perfect blend of durability and performance.

II. Corrosion Resistance:

The standout advantage of thin wall stainless steel pipes lies in their unparalleled resistance to corrosion. This attribute is of paramount importance in industries exposed to aggressive environments and corrosive substances. The dual-phase structure acts as a formidable defense mechanism against various forms of corrosion, including the insidious pitting, crevice corrosion, and stress corrosion cracking. Consequently, thin wall stainless steel tubes find ideal applications in chemical processing, oil and gas, marine engineering, and other corrosive environments.

III. Mechanical Strength and Durability:

Thin wall stainless steel tubes exhibit superior mechanical strength, making them well-suited for applications demanding high tensile strength and toughness. In comparison to austenitic and ferritic stainless steels separately, the combination in duplex pipes imparts enhanced mechanical properties. This characteristic proves valuable in industries such as construction, where structural integrity is paramount, and in transportation, where tubes must withstand extreme conditions, ensuring longevity and durability.

IV. Versatility Across Industries:

The versatility of thin wall stainless steel pipes is a hallmark feature, allowing for seamless integration across a diverse range of industries. From chemical and petrochemical plants to desalination facilities, these tubes showcase adaptability to various operational environments. Their resistance to corrosion, high strength, and compatibility with different fluid types make them invaluable in applications spanning from energy production to wastewater treatment, providing a versatile and reliable tubing solution.

V. Enhanced Performance in High-Temperature Environments:

Thin wall stainless steel pipes excel in high-temperature environments, a critical factor in industries such as power generation and chemical processing. Their ability to maintain mechanical strength and corrosion resistance at elevated temperatures positions them as reliable components for conveying hot fluids and gases. This capability not only contributes to the overall efficiency of industrial processes but also enhances safety in challenging thermal conditions.

VI. Economic Viability:

Beyond their technical advantages, thin wall stainless steel tubes offer economic benefits that further solidify their appeal. The extended lifespan of these tubes, coupled with reduced maintenance requirements, translates to significant cost savings over the long term. The durability and corrosion resistance of thin wall stainless steel pipes minimize the need for frequent replacements and repairs, making them a sustainable and economically viable choice for industries looking to optimize their budgetary considerations.

VII. Application in Oil and Gas Industry:

The oil and gas sector, known for its harsh operating conditions, has found a reliable ally in thin wall stainless steel pipes. These tubes play a crucial role in conveying corrosive hydrocarbons, acids, and gases, showcasing their exceptional resistance to corrosion and erosion. The duplex stainless steel’s ability to withstand the challenging environments of offshore drilling, subsea pipelines, and processing facilities makes it an ideal choice. It ensures the integrity of critical components in this vital industry, contributing to the overall safety and efficiency of oil and gas operations.

VIII. Corrosion Resistance in Chemical Processing:

In chemical processing plants, where exposure to corrosive substances is inherent, thin wall stainless steel tubes shine with their exceptional corrosion resistance. They effectively combat the corrosive effects of acids, alkalis, and other chemicals, ensuring the longevity of piping systems. The resistance to pitting and crevice corrosion, combined with high strength, positions these tubes as a cornerstone in chemical manufacturing. Maintaining the integrity of processing equipment is paramount in chemical plants, and thin wall stainless steel pipes prove to be a reliable solution.

IX. Contribution to Sustainable Desalination:

The desalination industry, addressing the global demand for freshwater, benefits significantly from the corrosion resistance and durability of thin wall stainless steel tubes. In desalination plants, where constant exposure to saltwater can pose a significant challenge, duplex stainless steel ensures longevity and reliability in the piping infrastructure. Its resistance to corrosion and erosion is pivotal in sustaining desalination processes, contributing to the production of clean and potable water. Thin wall stainless steel pipes play a crucial role in supporting sustainable solutions for the world’s growing water needs.

X. Role in Structural Applications:

Thin wall stainless steel tubes find extensive use in structural applications where both strength and corrosion resistance are critical. Infrastructure projects such as bridges, tunnels, and architectural structures benefit from the material’s ability to withstand the elements. The high mechanical strength of duplex stainless steel ensures the structural integrity of components in diverse constructions. Engineers and architects favor thin wall stainless steel pipes for their durability and longevity in designs where maintaining structural integrity is paramount.

XI. Performance in Challenging Environments:

Industries operating in challenging environments, such as marine engineering and coastal facilities, leverage the superior performance of thin wall stainless steel tubes. The material’s resistance to corrosion in saline and humid conditions makes it a preferred choice for structures exposed to seawater. Duplex stainless steel’s ability to withstand the harsh marine environment positions it as an essential component in shipbuilding, offshore platforms, and coastal infrastructure. Thin wall stainless steel pipes ensure the longevity and reliability of structures in environments where traditional materials might falter.

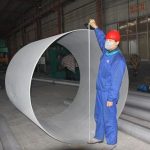

XII. Advances in Manufacturing Techniques:

The continuous evolution of manufacturing processes has further enhanced the properties of thin wall stainless steel pipes. Advanced techniques, including precision machining and improved quality control, contribute to the production of high-quality tubes with consistent mechanical properties. These advances ensure that industries receive products that meet stringent specifications, fostering confidence in their performance across various applications. The precision in manufacturing processes adds to the reliability and effectiveness of thin wall stainless steel pipes in diverse industrial settings.

XIII. Future Prospects and Ongoing Research:

As industries continue to demand materials that can meet evolving challenges, ongoing research and development in the field of thin wall stainless steel tubes hold promise. Researchers focus on refining the alloy composition, exploring new manufacturing methods, and expanding the scope of applications. The future may witness even more tailored duplex alloys catering to specific industry needs, pushing the boundaries of what is achievable with these advanced materials. Ongoing research ensures that thin wall stainless steel pipes remain at the forefront of technological advancements, offering solutions to emerging challenges in various sectors.

Conclusion:

In conclusion, the advantages of using thin wall stainless steel tubes over traditional tubing materials underscore their pivotal role in modern industrial applications. From metallurgical excellence to corrosion resistance, mechanical strength, versatility, and economic viability, these tubes offer a comprehensive solution to the diverse needs of industries ranging from oil and gas to chemical processing, desalination, structural engineering, and marine environments. As industries continue to evolve, thin wall stainless steel tubes emerge as a cornerstone in industrial tubing solutions, ensuring efficiency, longevity, and reliability in a wide array of applications.

Related Products