Both 304 stainless steel pipe and 316 stainless steel are the code names of stainless steel. In essence, they are no different. They are all stainless steel, but they are subdivided into different types. The quality of 316 stainless steel pipe is greater than that of 304 stainless steel pipe. 316 stainless steel pipe incorporates metal molybdenum on the basis of 304. This element can further strengthen the molecular structure of stainless steel, make it more wear-resistant and oxidation-resistant, and at the same time resist corrosion. Sex is also greatly increased. So what is the difference in the scope of application of the two?

304 stainless steel pipe application range

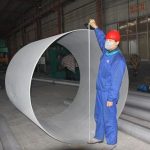

304 stainless steel pipe is a widely used chromium-nickel stainless steel pipe. As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; it has good hot workability such as stamping and bending. The heat treatment hardening phenomenon is resistant to corrosion in the atmosphere. If it is an industrial atmosphere or a heavily polluted area, it needs to be cleaned in time to avoid corrosion. Suitable for decoration and decoration fields, (stainless steel anti-theft windows, stainless steel stair handrails, etc.), auto parts (windshield wipers, mufflers, molded products), medical appliances, building materials, chemicals, food industry, agriculture, ship parts, etc. The effect of using 304 stainless steel pipe in a dry indoor environment is quite good. However, if you want to maintain its appearance outdoors in the countryside and cities, you need to wash it frequently. However, in severely corrosive industries or marine atmospheres, 316 stainless steel pipes are used.

316 stainless steel pipe application range

316 stainless steel pipe is a steel with superior corrosion resistance and other properties than 304. It is mainly used in petroleum, chemical, medical, food, mechanical and instrument CNC processing and other industrial pipelines. Coastal facilities and production equipment used in seawater also need to use 316L due to the high salt content of the environment. In addition, it is widely used in chemistry, construction, bridges, aerospace, mechanical hardware, medical treatment, decoration, medical fitness products, furniture, tableware manufacturing, liquid transportation, automobile manufacturing, water supply, solar energy, machinery manufacturing, nuclear power, architectural decoration, rail transit , Sanitary ware, metal products, containers and other industries.

When purchasing stainless steel decorative pipes, the environment in which the stainless steel decorative pipes are used determines the service life. The composition, temperature and pressure of the corrosive medium are important factors to consider when choosing a suitable stainless steel decorative pipe. Therefore, when choosing a stainless steel pipe, it should be selected according to the use situation.