Introduction:

Stainless Steel Pipe for Gas are widely used in the gas industry due to their durability, strength, and resistance to corrosion. They are available in various grades, each with unique properties that make them suitable for different applications. This article will cover everything you need to know about stainless steel pipe for gas, including their properties, applications, benefits, and installation best practices.

Properties of Stainless Steel Pipe for Gas:

- Corrosion Resistance – Stainless steel pipes are highly resistant to corrosion, making them ideal for use in harsh environments such as the gas industry.

- Strength and Durability – Stainless steel pipes are known for their strength and durability, making them capable of handling high pressures and temperatures.

- Heat Resistance – Stainless steel pipes are also heat-resistant, making them suitable for use in high-temperature applications.

- Hygiene – Stainless steel pipes are non-porous, making them easy to clean and maintain. They are also resistant to bacteria and other microorganisms, making them ideal for gas transport applications where cleanliness is essential.

- Aesthetic Appeal – Stainless steel pipes have a sleek and polished appearance, making them popular for architectural and decorative applications.

Applications of Stainless Steel Pipe for Gas:

- Natural Gas Distribution – Stainless steel pipes are commonly used in natural gas distribution systems due to their corrosion resistance and durability.

- Petroleum Refining – They are also used in petroleum refining processes due to their heat resistance and strength.

- Chemical Processing – Stainless steel pipes are ideal for transporting chemicals due to their resistance to corrosion and heat.

- Commercial and Residential HVAC Systems – They are also used in commercial and residential heating, ventilation and air conditioning systems because of their durability and strength.

Benefits:

- Corrosion Resistance – The most significant benefit of using stainless steel pipe for gas is its ability to resist corrosion, ensuring the longevity and integrity of the gas transportation system.

- Durability – stainless steel gas pipe is known for its durability, making it capable of handling high pressures and temperatures without cracking or leaking.

- Hygiene – Stainless steel pipes are non-porous and resistant to bacteria, making them ideal for applications where cleanliness is essential.

- Aesthetic Appeal – The sleek and polished appearance of stainless steel makes it a popular choice for architectural and decorative applications.

- Cost-Effective – While the initial cost of stainless steel gas pipe may be higher than other materials, their longevity and durability make them more cost-effective in the long run.

Installation Best Practices:

Proper installation of stainless steel gas pipe is crucial to ensuring its longevity and performance. Best practices include proper alignment, support, and anchoring, avoiding over-tightening of fittings, using appropriate sealants and joint compounds, and following industry standards and regulations for gas transport systems.

Types

Stainless steel pipes come in various types, each with unique properties that make them suitable for different applications. These types include austenitic, ferritic, duplex, and martensitic stainless steel pipes. It is important to understand the differences between these types to choose the right piping material for your specific gas transportation needs.

Manufacturing Process

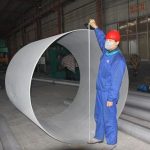

stainless steel gas pipe is manufactured using a process known as cold rolling or cold drawing. This involves passing the metal through rollers or drawing it through a die at a low temperature, which improves its strength and hardness while maintaining its ductility. The resulting pipe is then annealed, which relieves internal stresses and makes it easier to work with.

Maintenance and Care

To ensure that stainless steel gas pipe maintains its durability and corrosion resistance, it is essential to clean and maintain it regularly. This includes avoiding harsh chemicals and abrasive materials, wiping up spills immediately, and ensuring proper drainage to prevent stagnation of gas or other fluids that can cause corrosion.

How to Choose

Choosing the right supplier of stainless steel gas pipe is crucial to ensuring the quality and reliability of your gas transportation system. It is important to choose a supplier with a proven track record of providing high-quality

stainless steel products for the gas industry, who offers reliable customer service and support. Look for suppliers who have certifications and accreditations that demonstrate their commitment to quality and safety, such as ISO 9001 and ASME certifications.

Advancements

Advancements in stainless steel technology continue to improve the quality and performance of stainless steel gas pipe. The development of new alloys and manufacturing processes has resulted in increased strength, durability, and corrosion resistance. Additionally, innovations in coatings and surface treatments have improved the aesthetic appeal and hygiene properties of stainless steel pipe for gas.

Conclusion:

In conclusion, stainless steel pipe for gas is a reliable and durable option for various applications in the gas industry. Its unique properties, including corrosion resistance, strength and durability, heat resistance, hygiene, and aesthetic appeal, make it a popular choice for natural gas distribution, petroleum refining, chemical processing, and commercial and residential HVAC systems. Understanding the benefits of stainless steel pipe for gas, as well as installation best practices, can ensure that your gas transportation system performs optimally, maintaining its integrity and longevity. As advancements in stainless steel technology continue to improve, Stainless Steel gas pipe will remain a critical component in ensuring safe, reliable, and efficient gas transportation worldwide.

Related Products