In the evolving landscape of societal advancement, the food and pharmaceutical sectors are raising the bar for product quality and production environments. Stainless steel pipes have become indispensable in meeting these heightened demands, particularly in these industries, thanks to their outstanding sanitary properties and environmental benefits. This piece delves into the hygienic attributes of stainless steel pipes, investigates their role in fostering a clean production environment, and highlights the distinct advantages and typical material applications of these pipes.

Sanitary Characteristics of Stainless Steel Pipes:

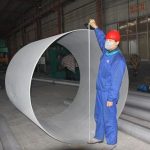

The food and pharmaceutical sectors place a premium on maintaining high levels of purity and hygiene in their products, making the material choice for conveyance pivotal. Stainless steel pipes are highly favored due to their sleek surfaces, absence of burrs, and minimal splashing. To begin with, the polished surface of stainless steel discourages the adherence of bacteria, microorganisms, and other potentially harmful substances, effectively minimizing the risk of cross-contamination and ensuring the hygiene and safety of products. Additionally, stainless steel showcases remarkable corrosion resistance, is less susceptible to rusting, and does not release any harmful substances, thereby guaranteeing the purity of the transported products.

Creating a Pollution-Free Environment:

Maintaining a pollution-free environment is paramount in food and pharmaceutical production. The application of stainless steel pipes contributes to establishing a pollution-free production environment. The smooth and easily cleanable surface of stainless steel prevents residue buildup, facilitating more efficient cleaning of production lines. Additionally, the strong sealing performance of stainless steel pipes prevents contamination from external air and dust, ensuring that products remain in a clean environment throughout the conveying process. Through thoughtful design and layout, the likelihood of cross-contamination can be minimized, providing a safer and purer environment for production.

Contrast with Traditional Conduits:

In traditional food and pharmaceutical industries, common conduits include plastic pipes, rubber pipes, and metal pipes. However, these traditional conduits exhibit several drawbacks in terms of hygiene, corrosion resistance, and environmental friendliness when compared to stainless steel pipes, highlighting the importance of the latter.

- Drawbacks of Plastic Pipes:

- Prone to contamination: The uneven surface of plastic pipes easily attracts microorganisms, bacteria, and other contaminants, increasing the risk of cross-contamination and making them unsuitable for the high hygiene requirements of the food and pharmaceutical industries.

- Poor corrosion resistance: Plastic pipes may suffer chemical corrosion in some pharmaceutical production environments, leading to aging, deformation, and adverse effects on production efficiency.

- Unsuitability for high temperatures: In high-temperature environments, plastic pipes are prone to softening and deformation, limiting their application in high-temperature production processes.

- Drawbacks of Rubber Pipes:

- Susceptible to aging: Rubber pipes are easily affected by light, oxygen, and chemicals, leading to aging and cracking, impacting their lifespan.

- Incompatibility with high temperatures: Rubber loses elasticity at high temperatures, making it unsuitable for prolonged use in high-temperature environments.

- Limited corrosion resistance: Rubber exhibits poor resistance to some strong acids and bases, restricting its application in certain specialized production environments.

- Drawbacks of Metal Pipes:

- Corrosiveness: Some traditional metal pipes may corrode, causing the dissolution of metal ions and contaminating products.

- Heavy weight: Metal pipes are relatively heavy, resulting in higher installation and maintenance costs. Moreover, they are less malleable in certain production processes.

Advantages of Stainless Steel Pipes:

- Sanitary characteristics: Smooth surfaces and lack of burrs make stainless steel pipes ideal for industries with high hygiene requirements.

- Corrosion resistance: Excellent resistance to corrosion reduces the risk of product contamination due to pipe corrosion in harsh environments.

- High-temperature and high-pressure resistance: Stainless steel pipes can withstand demanding production environments, ensuring the stable conveyance of products.

- Long lifespan: Stainless steel pipes are durable, with a longer lifespan, reducing maintenance costs.

- Environmental friendliness: Stainless steel is recyclable, aligning with environmental principles and presenting a clear contrast to single-use plastic pipes.

In summary, the outstanding performance of stainless steel pipes stands out among traditional conveying tools in the traditional food and pharmaceutical industries, highlighting their irreplaceability in improving production efficiency, ensuring product quality, and guaranteeing hygiene and safety. With the continuous improvement of industry hygiene standards, stainless steel pipes are destined to become the preferred pipeline material in food and pharmaceutical production.

The manufacturing process of stainless steel pipes undergoes a series of precision processes to ensure high quality and hygiene standards. Here are the main steps in the manufacturing process of stainless steel pipes:

- Raw Material Preparation: The manufacturing of stainless steel pipes begins with the selection of high-quality stainless steel raw materials. Common stainless steel materials include 304, 316L, 2205, and 904L, depending on specific environmental and industry requirements.

- Pipe Billet Preparation: The chosen stainless steel material is processed into pipe billets through methods such as hot rolling or cold drawing. Hot rolling involves heating the stainless steel billet to an appropriate temperature and rolling it into a pipe shape, while cold drawing stretches the billet into a pipe shape through cold processing.

- Welding: The pipe billets are then welded together using welding processes to achieve the desired dimensions and lengths. Common welding methods include TIG (tungsten inert gas welding), MIG (metal inert gas welding), and resistance welding. Welding is a critical step in ensuring the sealing and strength of the pipes.

- Pipe Forming: The pipes go through forming processes, such as extrusion and stretching, to achieve the specified diameter and wall thickness. This step helps improve the mechanical performance of the pipes.

- Heat Treatment: To enhance the hardness and corrosion resistance of stainless steel pipes, they undergo a heat treatment process. Heat treatment helps improve the pipe’s microstructure and enhance its physical and chemical properties.

- Surface Treatment: Finally, the surface of the pipes undergoes polishing, sandblasting, and other treatments to ensure a smooth and clean surface. This helps reduce the attachment of bacteria and microorganisms, enhancing hygiene standards.

Common Applications of Stainless Steel Pipe Materials:

- 304 Stainless Steel:

- General-purpose stainless steel with good corrosion resistance and processing performance, commonly used in the food industry.

- 316L Stainless Steel:

- Contains higher nickel and molybdenum elements, offering better corrosion resistance. Commonly used in the pharmaceutical industry, especially in applications requiring higher purity.

- 2205 Duplex Stainless Steel:

- Possesses characteristics of both austenitic and ferritic stainless steel, providing better corrosion resistance and strength. Suitable for some special conveying needs in specific environments.

- 904L Stainless Steel:

- Extremely corrosion-resistant, suitable for use in extremely corrosive environments, such as the chemical pharmaceutical field.

Conclusion: Stainless steel pipes, as crucial conveying tools in the food and pharmaceutical industries, provide reliable support for industry production due to their hygienic properties, pollution-free environment, and unique advantages. With ongoing technological advancements, the application of stainless steel pipes is expected to broaden, injecting new momentum into the development of the food and pharmaceutical industries. In future production, we can anticipate stainless steel pipes playing an even more crucial role in driving industry hygiene standards and improving production efficiency.

Company Introduction:

We are a dedicated provider of high-quality stainless steel products. Over the years, we have focused on research, development, manufacturing, and supply of stainless steel materials, delivering reliable solutions to customers across various industries. Our mission is to meet customer needs and provide the highest quality stainless steel products in a sustainable and innovative manner.

Why Choose Us?

- Quality Assurance: Our stainless steel products undergo strict quality control and testing, ensuring performance and reliability that meet high standards.

- Wide Product Range: We offer a variety of specifications and grades of stainless steel materials to meet the requirements of diverse applications.

- Expertise: Our experienced team provides professional advice and support to our customers.

- Sustainability Commitment: We are committed to reducing our environmental impact through recycling and eco-friendly practices, contributing to sustainability.

We mainly producing stainless steel pipe(304,304L,321,316L,316Ti,310S,347H,904L etc.),duplex pipe(S32304,S31803,S32205,S32750,S31260,S32760 etc.), ss flange, and nickel alloy products(600,601,625,276,400,800 etc.).

If you have any questions about our stainless steel products or services, or require further information, please do not hesitate to get in touch. Our team is dedicated to serving you.

Whether you are seeking stainless steel solutions or have inquiries about our stainless steel products, we look forward to collaborating with you and providing outstanding service.