Introduction:

Stainless steel welded pipe is a type of piping material that is widely used in various industries due to its excellent corrosion resistance, strength, and durability. It is made by welding together two or more pieces of stainless steel, creating a seamless and strong connection. This article will cover everything you need to know about stainless steel welded pipe, including its properties, applications, benefits, and installation best practices.

Properties:

- Corrosion Resistance – stainless pipe welding has excellent corrosion resistance, making it suitable for use in harsh environments such as chemical processing plants and offshore oil rigs.

- Strength and Durability – stainless pipe welding is known for its strength and durability, making it capable of handling high pressures and temperatures.

- Heat Resistance – stainless pipe welding is also heat-resistant, making it ideal for use in high-temperature applications.

- Hygiene – stainless pipe welding is non-porous, making it easy to clean and maintain. It is also resistant to bacteria and other microorganisms, making it ideal for use in food processing plants and medical facilities.

- Cost-Effective – stainless pipe welding is relatively affordable compared to other types of stainless steel piping materials, making it an attractive option for many industries.

Applications:

- Chemical Processing – stainless pipe welding is commonly used in chemical processing plants due to its corrosion resistance and durability.

- Food Processing – It is a popular choice in the food processing industry due to its hygienic properties and resistance to bacteria.

- Water Distribution – stainless pipe welding is ideal for water distribution systems due to its durability and resistance to corrosion.

- Architecture and Design – Its sleek and polished finish make it a popular choice for architectural applications such as handrails, balustrades, and decorative features.

- Oil and Gas – It is widely used in the oil and gas industry due to its resistance to harsh environmental conditions.

Benefits :

- Corrosion Resistance – The most significant benefit of using stainless pipe welding is its ability to resist corrosion, ensuring the longevity and integrity of piping systems.

- Durability – stainless pipe welding is known for its durability, making it capable of handling high pressures and temperatures without cracking or leaking.

- Hygiene – stainless pipe welding is non-porous and resistant to bacteria, making it ideal for applications where cleanliness is essential.

- Aesthetic Appeal – The sleek and polished appearance of stainless pipe welding makes it a popular choice for architectural and decorative applications.

- Cost-Effective – Despite its many benefits, stainless pipe welding is relatively affordable compared to other types of piping materials.

Installation Best Practices:

Proper installation of stainless pipe welding is crucial to ensuring its longevity and performance. Best practices include proper alignment, support, and anchoring, avoiding over-tightening of fittings, using appropriate sealants and joint compounds, and following industry standards and regulations for the specific application and location of the piping system.

Types:

stainless pipe welding comes in various types, including longitudinal welded, spiral welded, and electric fusion welded. Each type has unique properties that make it suitable for different applications. It is important to understand the differences between these types to choose the right piping material for your specific needs.

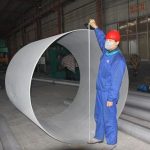

Manufacturing Process:

stainless pipe welding is manufactured by welding together two or more pieces of stainless steel using various methods such as TIG or MIG welding. After welding, the resulting pipe is annealed to relieve internal stresses and improve its strength and ductility.

Maintenance and Care:

To ensure that stainless steel welded pipe maintains its durability and corrosion resistance, it is essential to clean and maintain it regularly. This includes avoiding harsh chemicals and abrasive materials, wiping up spills immediately, and ensuring proper drainage to prevent stagnation of water or other fluids that can cause corrosion.

Conclusion:

In conclusion, stainless steel welded pipe is a reliable and durable option for various applications in different industries. Its unique properties, including corrosion resistance, strength and durability, heat resistance, hygiene, and cost-effectiveness, make it a popular choice for chemical processing, food processing, water distribution, architecture and design, and oil and gas applications. Understanding the benefits of stainless pipe welding, as well as installation best practices, can ensure that your piping system performs optimally, maintaining its integrity and longevity. As stainless steel continues to be a popular choice in different industries, stainless steel welded pipe will continue to play a critical role in ensuring the safety, reliability, and longevity of piping systems worldwide.

Related Products