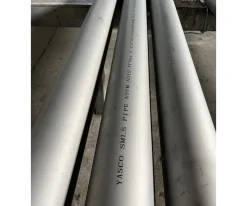

ASTM A312 Standard Overview

ASTM A312 is the core specification for austenitic stainless steel seamless, welded, and heavy cold-finished pipe. The standard was developed by the American Society for Testing and Materials (ASTM).

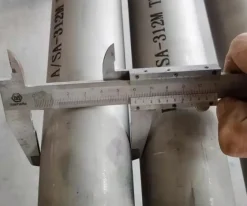

This standard covers a diameter range from 1/8 inch (6.4 mm) to 30 inches (760 mm), with wall thicknesses spanning from SCH 5S to SCH XXS grades.

ASTM A312 pipe is suitable for high temperature, corrosive environments, and low temperature environments. It is a key material in various industrial fields such as chemical, energy and food industries.

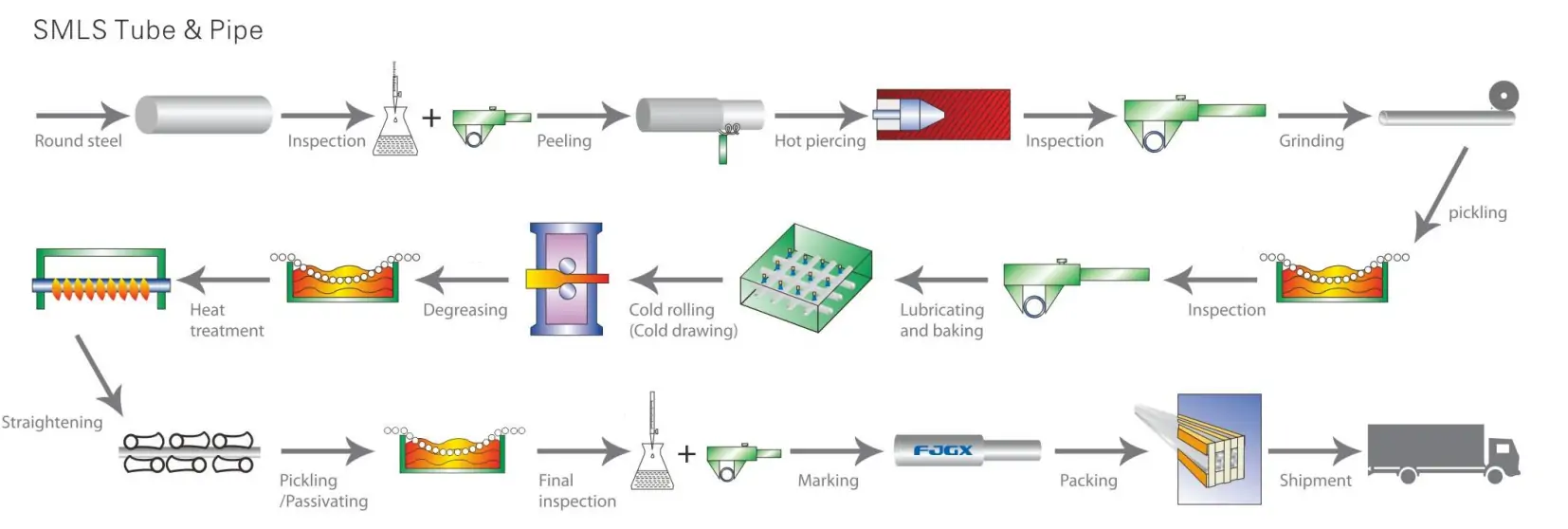

Manufacturing Process Classification

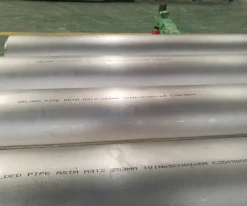

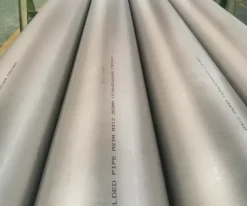

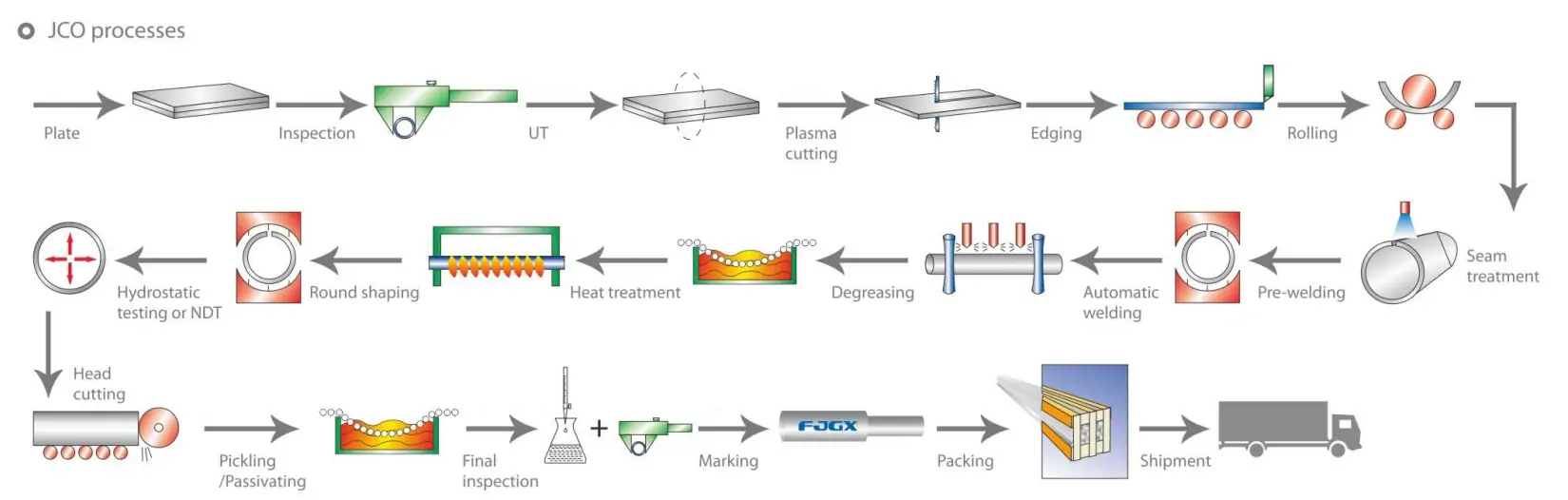

Welded Pipes:

Manufactured by rolling austenitic stainless-steel sheets, these pipes are formed through automatic welding methods such as TIG (Tungsten Inert Gas) or laser welding. The weld seams must undergo radiographic or ultrasonic testing to ensure quality. They are delivered in a state of heat treatment (solution annealing) combined with pickling and passivation. This process eliminates internal stresses and enhances corrosion resistance by 346 (presumably a factor or value indicating the improvement degree).

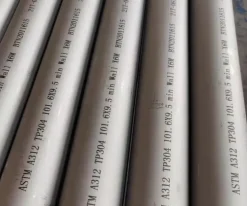

Seamless Pipes:

Seamless pipes are made by hot piercing (heating the pipe to 1200°C) or cold rolling/cold drawing. This pipe has no welds and has a uniform structure throughout, making it suitable for high-pressure applications. Its burst strength can be 2 to 3 times that of welded pipes.

Technical Features

Heavily Cold – Worked Pipes

During the cold – working process, a high degree of deformation is applied, which improves the strength and surface precision of the pipes. They are ideal for use in precision instruments.

Heat Treatment and Microstructural Control

All steel pipes are required to undergo solution treatment: heated to a temperature of ≥1040°C, followed by rapid cooling, which restores the stability of the austenitic structure.

For H-grade materials (such as TP316H), a higher treatment temperature (≥1100°C) is required to ensure creep resistance at high temperatures.

Grain Size Control: For example, TP310H needs to achieve a grain size of Grade 6 or coarser as per the ASTM E112 standard, which optimizes its stress-rupture resistance.

Manufacturing Process of Welded and Seamless Pipes

Seamless Stainless Steel Pipe

Welded Stainless Steel Pipe – JCO Process

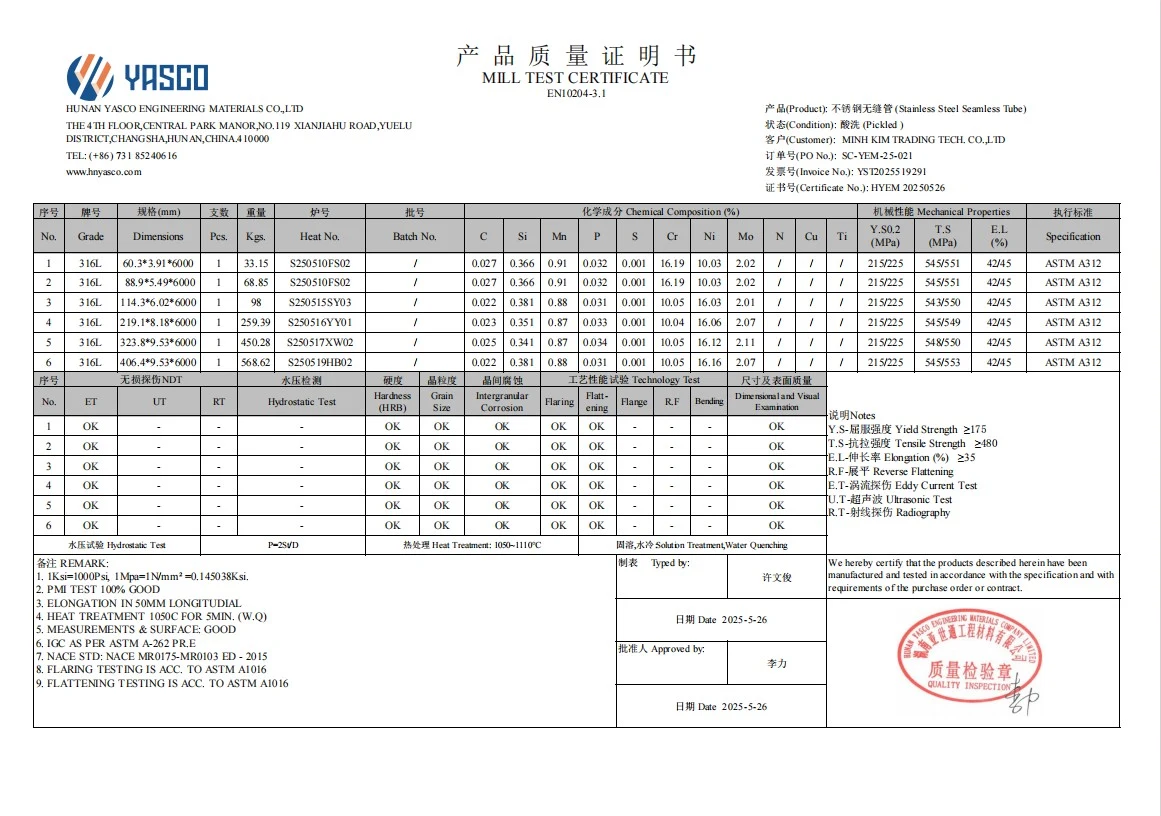

Quality Control and Certification Guarantee for ASTM A312 Standards

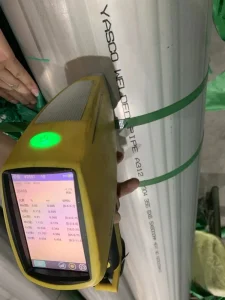

Full Process Inspection Requirements

- Raw Materials: Spectral analysis is conducted to verify the chemical composition. For example, the nickel (Ni) content of TP304L should reach 8–12%.

- Manufacturing Process: X – ray flaw detection for weld seams and hydrostatic pressure tests (with the pressure ≥ 1.5 times the design value) are carried out .’

- Finished Products:

- Flattening tests for welded pipes or flaring tests for seamless pipes are performed to verify ductility.

- Intergranular corrosion tests (in accordance with ASTM A262) are carried out to detect the risk of sensitization.

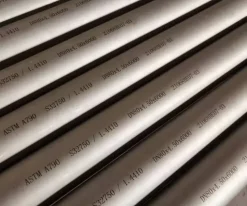

- International Standard Mutual Recognition: This standard is equivalent to international systems such as ISO, EN, and JIS. For example, TP316L corresponds to European standard 1.4404 and Chinese standard 00Cr17Ni12Mo2 [10], facilitating procurement for global projects.

Standard System and Performance

Core Requirements of ASTM A312

- Chemical Composition: Strict limits are imposed on elements such as carbon, chromium, and nickel. For instance, in the case of TP316L, the chemical composition is specified as: carbon (C) ≤ 0.03%, chromium (Cr) 16–18%, and molybdenum (Mo) 2–3%

- Mechanical Properties: Taking TP316L as an example, its mechanical properties are as follows: tensile strength ≥ 485 MPa, yield strength ≥ 170 MPa, and elongation ≥ 40%

- Low – Temperature Toughness: Grades like TP304 and TP304L can directly obtain the ASME B31.3 certification at –250°C without the need for impact testing.

Scope and Differences differece among ASTM A 312,ASTM A 213 and Astm a 269

| Standard | Primary Purpose | Scope of Application | Design Focus |

| ASTM A312 | General industrial piping | High-temp (≤815°C), corrosive environments (chemical, energy, marine); covers seamless, welded, heavily cold-worked pipes | Balanced corrosion resistance + high-temp strength, lifecycle cost efficiency |

| ASTM A269 | Standard tubing for general equipment | Ambient to medium temps (≤400°C), mild corrosion (food/pharma); seamless/welded pipes accepted | Basic corrosion protection, cost-effectiveness |

| ASTM A213 | High-temp/pressure service tubing | Boilers, superheaters, heat exchangers (≥500°C); seamless pipes only | Creep resistance + stress rupture performance for long-term high-temp reliability |

Key Distinctions:

- A312: Industrial versatility, corrosion + high-temp balance, flexible manufacturing;

- A269: Economical corrosion protection for non-critical services;

- A213: Extreme high-temp/pressure reliability, seamless-only for safety.

ASTM A 312 stands as a universally recognized and widely adopted standard for stainless steel pipes and tubes, renowned for its broad applicability across diverse industries and applications. This standard encompasses a comprehensive range of stainless steel alloys, including austenitic grades like 304, 304L, 316, and 316L, which are celebrated for their exceptional corrosion resistance, high-temperature durability, and mechanical strength. Its (broad-spectrum nature) is underscored by its design to cater to both seamless and welded stainless steel products, allowing flexibility in manufacturing processes while maintaining rigorous quality and performance benchmarks.

Industries ranging from chemical processing, petroleum, and power generation to food and beverage, pharmaceuticals, and architectural construction rely on ASTM A 312 due to its ability to address diverse operational demands

If you have any demands for such stainless steel pipe or not sure which grade will use , please contact us by aurora@hnyasco.com . We will offer our technical assistance for your any concerns.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)